Description

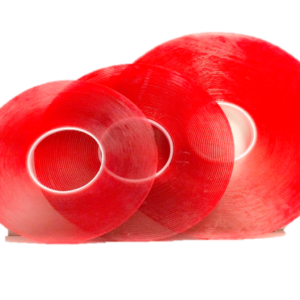

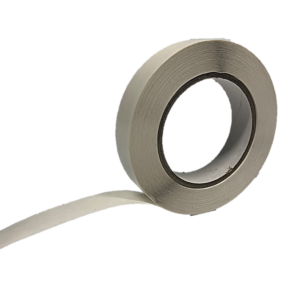

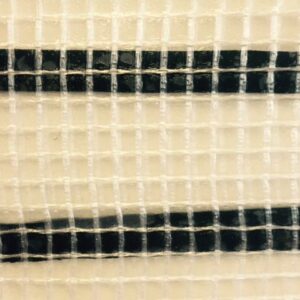

A double-sided, black acrylic foam tape, designed for difficult to stick substrates – Low Surface Energy.

High performance, excellent for bonding low and medium surface energy materials e.g. Powder Coated Metal, Plastics etc.

Offers design flexibility with it’s viscoelasticity and powerful ability to bond to a variety of surfaces.

Suitable for long term bonding applications indoor and outdoor.

Unaffected by UV.

High Temperature resistance.

Available in various Widths.

Reviews

There are no reviews yet.