Description

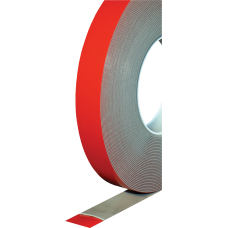

Double sided, with filmic liner.

A versatile, structural bonding tape suitable for use within numerous applications and industries; such as Construction, Signage, Auto, Interiors, Aerospace and Defence.

Exceptional bonding capabilities comprised with outstanding load bearing characteristics, confidently used to replace traditional adhesives, spot welds, rivets, screws, nuts and bolts.

Especially developed for intensive use in extreme environments and able to withstand temperatures ranging from -40°C to +200°C.

Unaffected by ageing and UV (no discoloration) and suitable for both internal and external, all weather use.

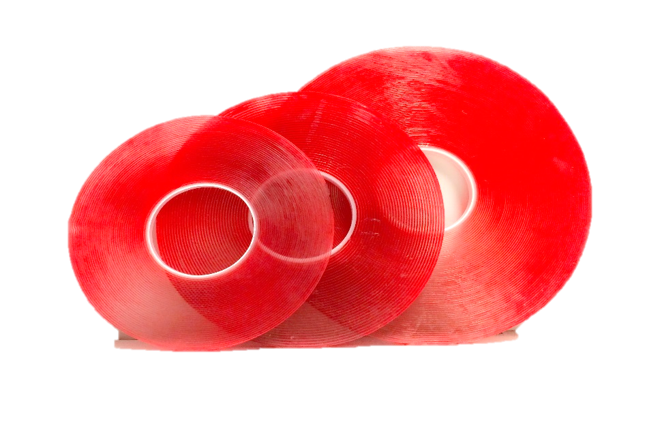

Roll Lengths:

0.5mm and 1.0mm thickness – 33 Metres

1.5mm and 2.0mm thickness – 16.5 Metres

Reviews

There are no reviews yet.