Description

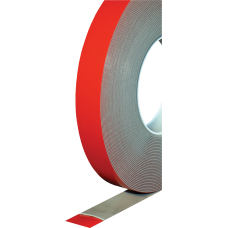

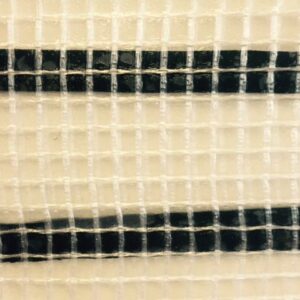

Double sided, with filmic liner.

A 2mm thick, foamed acrylic adhesive tape. Ideal for the aesthetic matching of adhesive to substrate, for covering over unsightly blemishes or blocking out screw holes and joins.

The grey adhesive is perfect for engineering and the bonding of metals, whilst the white is often preferable when bonding to extruded plastics.

Sold in a range of widths and thicknesses. Also available in White. Please call us for more options.

Reviews

There are no reviews yet.